Many of today’s manufacturers are constantly faced with the increased demands of high-speed operations, coupled with extreme levels of precision. These unique requirements drive the need for machinery and tools to avoid friction to operate with high accuracy and reliability.

While a variety of bearings are available on the market to reduce friction, each work differently and offer a different level of performance. Traditional roller bearings contact surfaces during operation and generate heat, resulting in wear and machine performance. Air bearings are being chosen across a wide range of applications to overcome these deficiencies.

While air bearings offer a clear improvement, it is critical to know there are various designs available with differentiating features.

Air bearings from New Way® offer superior performance over roller bearings. Our signature Porous Media Technology™ provides a unique method for air distribution making it the preeminent choice among air bearing designs.

Here’s What the Experts Say about Air Bearings

According to Linear Motion Tips, a primary benefit of air bearings is the elimination of friction-induced wear, heat generation, and the need for lubrication. Without recirculating elements, air bearings achieve higher speeds than a ball or roller bearing. The publication also points out that the fluid film in air bearings compensates for small-scale errors for more accurate motion than mechanical bearings.

The following table outlines the performance differences between New Way Porous Media Air Bearings and conventional roller bearings:

| Porous Media Air Bearings | Rolling Element Bearings |

|---|---|

| Straighter motion for optimum positioning. | Momentum of balls amplifies unwanted bearing motion causing precision deviations. |

| High speeds at an order of magnitude greater than conventional roller element bearings. | Contact with the rail or guideway and multiple ball velocities limit the speed capabilities. Balls or rollers can slip at high acceleration. |

| Smooth and silent operation without vibrations. | Recirculating rollers or balls cause velocity ripples that compromise stability and performance. |

| Zero friction and zero wear for consistent, long-term performance at a higher resolution. | Balls show wear from mechanical contact resulting in inconsistent machine characteristics. |

| Elimination of lubricants and low particle generation avoid environmental contamination in cleanrooms. In dusty environments, air bearings push away dust. | Oil lubrication required by rolling element bearings can puddle, contaminating the area. |

How New Way Air Bearings Work

What sets New Way apart from other air bearing suppliers?

New Way Air Bearings incorporate Porous Media Technology which utilizes the natural permeability of porous carbon to control and create a uniform distribution of air pressure across the bearing surface creating a number of unique benefits:

- Ability to fly at small air gaps making them crash tolerant

- Difficult to clog

- Ability to operate correctly even if a bearing is scratched

- Greater stability and stiffness (see Graphic one)

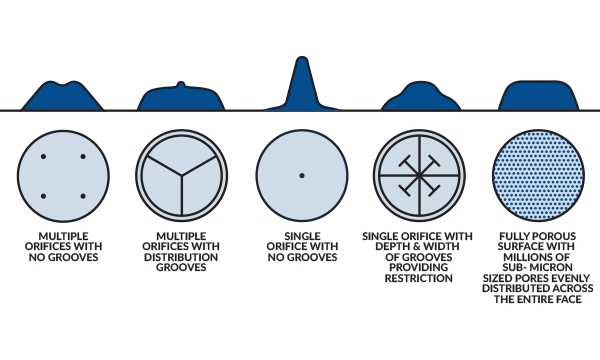

Competing air bearing designs, such as orifice-based air bearings, are unable to provide a consistent, even flow of air, limiting their benefits (see Graphic One).

Graphic One: Comparison of orifice vs. porous media air bearing technology that features millions of sub-micron holes for better air distribution that results in greater stability and stiffness.

Constructed of hard-coated aluminum or stainless steel, orifice bearing surfaces are easily scratched, impacting fly height and potentially causing a costly crash. Users also must carefully choose an orifice air bearing with the right number, size, and distribution of jeweled holes to maintain air stability during operation.

Reasons like this explain the increasing number of manufacturers turning to Porous Media™ air bearings across a wide range of industries.

See the Advantages of Air Bearings in Action!

In our video library, you’ll find animations demonstrating the differences in performance between porous media air bearings and conventional rolling element bearings across eight critical characteristics.

[global key=’wrap_class’ value=’text-center’] [global key=’hide_title’ value=’1′] [global key=’videos_cat’ value=’127′] [template file=’view/videos/index.php’][fullwidth class=’feature-2 text-center’ center=’center-wide’] [grid class=’sm-grid-1 md-grid-1 lg-grid-2 xl-grid-2 justify-center’]